Explore levers: their types, how they work, and practical uses. Learn about first, second, and third-class levers, mechanical advantage, and more.

Levers are cool tools that make work easier. They help you lift heavy stuff with less effort. In this article, we will look at what levers are, the different types like first-class, second-class, and third-class levers, and how they work. You will see how levers use a fulcrum and how they can change the way you lift and move things. We’ll also talk about real-life uses and how to calculate their mechanical advantage. Stick around to learn more about these amazing machines!

What is a Lever?

A lever is a rigid bar that pivots around a fixed point known as the fulcrum. The lever works by applying force at one end of the bar to lift or move a load at the other end. This simple mechanism can greatly amplify the force applied, making it easier to move or lift objects.

Historical Overview

Levers have a rich history. Ancient civilizations, such as the Greeks and Egyptians, used levers in construction and warfare. For instance, the great scientist Archimedes famously said, “Give me a place to stand, and I will move the Earth.” This quote highlights the power of levers and their impact on mechanical advantage.

Types of Levers and Their Classifications

Levers are classified into three main types based on the relative positions of the fulcrum, effort, and load. Each type offers different mechanical advantages and is used for various applications.

First-Class Levers

In a first-class lever, the fulcrum is positioned between the effort and the load. Common examples include a seesaw and a crowbar. These levers can be used to change the direction of force and often provide a significant mechanical advantage.

Second-Class Levers

In a second-class lever, the load is positioned between the fulcrum and the effort. Examples of this type include a wheelbarrow and a bottle opener. These levers are designed to increase force efficiency, making them ideal for lifting heavy loads with less effort.

Third-Class Levers

In a third-class lever, the effort is applied between the fulcrum and the load. Common examples include a fishing rod and tweezers. While these levers do not offer as much mechanical advantage as the others, they are excellent for increasing the speed and range of motion.

How Levers Work: Mechanics and Forces

Levers operate based on the principles of leverage and torque. Understanding these concepts is crucial for utilizing levers effectively.

Principles of Leverage

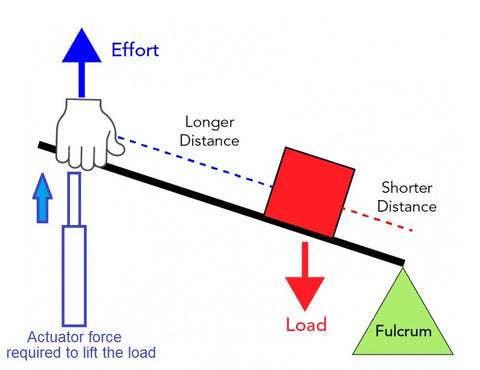

The fundamental principle of a lever is that it can amplify force. By applying force to one end of the lever, the other end can lift or move a load with less effort. This is achieved by changing the direction and magnitude of the applied force.

Mechanical Advantage

Mechanical advantage is the ratio of the output force to the input force. It determines how effectively a lever amplifies the applied effort. This calculation helps in understanding how levers can be used to move heavier loads with less force.

Torque and Force Distribution

Torque is the rotational force produced by a lever. It is calculated by multiplying the force applied by the distance from the fulcrum. This concept is essential for understanding how levers balance loads and distribute forces effectively.

Practical Applications of Levers

Levers are used in a wide range of applications, from everyday household items to complex industrial machinery.

Everyday Uses

You encounter levers daily. For example, a can opener uses a lever to puncture and open cans with minimal effort. Similarly, pliers use levers to grip and manipulate objects.

Industrial and Engineering Applications

In industrial settings, levers are integral to machinery and tools. For example, hydraulic presses use levers to amplify force for various manufacturing processes. The use of levers in engineering enhances productivity and efficiency.

Calculating Mechanical Advantage in Levers

Understanding how to calculate mechanical advantage is crucial for using levers effectively. The basic formula, as mentioned earlier, involves the ratio of the lengths of the effort and load arms. By applying this formula, you can determine the efficiency of different levers and make informed decisions about their use.

Factors Affecting Mechanical Advantage

Several factors influence mechanical advantage, including the fulcrum position and lever arm lengths. Adjusting these factors can optimize the performance of a lever and improve its effectiveness.

The Role of Fulcrum in Lever Systems

The fulcrum is a critical component of a lever. It serves as the pivot point around which the lever rotates.

Types of Fulcrums

Fulcrums can be fixed or movable. A fixed fulcrum remains stationary, while a movable fulcrum can change position. Each type of fulcrum affects how the lever functions and is chosen based on the desired outcome.

Impact on Lever Functionality

The position of the fulcrum greatly affects the lever’s performance. Moving the fulcrum closer to the load increases the mechanical advantage, while positioning it closer to the effort decreases it. Understanding this impact helps in designing and using levers effectively.

Comparing Different Classes of Levers

Each class of lever has its advantages and disadvantages, which determine its suitability for various tasks.

Advantages and Disadvantages

- First-Class Levers: Change the direction of force but may require significant effort to move heavy loads.

- Second-Class Levers: Provide high mechanical advantage and are excellent for lifting heavy objects.

- Third-Class Levers: Offer increased speed and range of motion but less mechanical advantage.

Case Studies and Examples

Real-world examples illustrate the effectiveness of each lever class. For instance, a wheelbarrow (second-class lever) is ideal for carrying heavy loads with less effort, while a fishing rod (third-class lever) allows for precise control and increased casting distance.

Innovations and Modern Uses of Levers

Levers continue to evolve with advancements in technology. Modern levers incorporate new materials and designs to enhance their functionality.

Technological Advancements

Recent innovations include composite materials that improve lever strength and durability. Advanced engineering has also led to the development of more efficient lever systems used in various industries.

Future Trends

Future trends in lever technology may include smart levers integrated with sensors and automation. These advancements could further enhance the efficiency and versatility of levers in various applications.

Troubleshooting and Maintenance of Lever Systems

Maintaining lever systems is essential for their optimal performance.

Common Issues

Common problems with levers include worn-out fulcrums and misaligned arms. Identifying these issues early can prevent more significant problems and ensure smooth operation.

Maintenance Tips

Regular maintenance involves checking for wear and tear, lubricating moving parts, and ensuring proper alignment. Keeping levers in good condition will extend their lifespan and maintain their effectiveness.

By understanding the principles and applications of levers, you can better appreciate their role in both everyday life and advanced technology. From lifting heavy objects to making precise movements, levers are an essential part of the mechanical world.

In summary, levers are vital for simplifying tasks by amplifying force. We covered their types, how they work, and their practical uses. Feel free to leave a comment, share this article, or explore more content on our website to dive deeper into the world of mechanical advantage and engineering.

FAQs about Levers

What is a lever and how does it work?

A lever is a simple machine consisting of a rigid bar that rotates around a fixed point called the fulcrum. When force is applied to one end of the lever, it moves the load at the other end. The lever amplifies the force applied, making it easier to lift or move objects. By changing the position of the fulcrum and adjusting the lengths of the arms, levers can provide different mechanical advantages.

What are the different types of levers?

Levers are classified into three main types:

- First-Class Levers: The fulcrum is positioned between the effort and the load. Examples include a seesaw or a crowbar.

- Second-Class Levers: The load is positioned between the fulcrum and the effort. Examples include a wheelbarrow or a bottle opener.

- Third-Class Levers: The effort is applied between the fulcrum and the load. Examples include a fishing rod or tweezers.

Each type has unique characteristics and is suited for different tasks.

How do you calculate the mechanical advantage of a lever?

The mechanical advantage of a lever is calculated using the formula. This ratio determines how effectively a lever amplifies the applied force. A higher mechanical advantage means that less effort is needed to lift or move a heavier load.

What is the role of the fulcrum in a lever?

The fulcrum is the pivotal point around which a lever rotates. Its position significantly impacts the lever’s mechanical advantage and overall effectiveness. By adjusting the fulcrum’s location, you can change the force needed to lift a load and how the lever performs.

How are levers used in everyday life?

Levers are found in many everyday tools and devices, including:

- Can openers: Use levers to puncture and open cans.

- Pliers: Employ levers to grip and manipulate objects.

- Scissors: Function as a pair of levers to cut materials.

These common tools illustrate how levers make tasks easier by amplifying the applied force.