Heavy forging is a critical industrial process that transforms raw metal into high-strength components used in various sectors, including automotive, aerospace, and construction.

In Pakistan, the heavy forging industry has experienced notable growth, driven by increasing demand for durable metal products and advancements in technology.

This article explores how heavy forging work is conducted in Pakistan, highlighting the techniques, benefits, and future prospects of this vital industry.

Overview about Heavy Forging

Heavy forging involves shaping metal using compressive forces, typically achieved through hydraulic presses or hammers.

This process enhances the metal’s mechanical properties, making it stronger and more resistant to wear and tear.

The heavy forging industry in Pakistan plays a crucial role in supplying components for machinery, automotive parts, and structural applications.

The Forging Process in Pakistan

1. Raw Material Selection

The quality of the forged product largely depends on the raw materials used. In Pakistan, manufacturers often source steel and alloy materials from local suppliers or import them to ensure high standards.

The selection of raw materials is vital, as it determines the final product’s durability and performance.

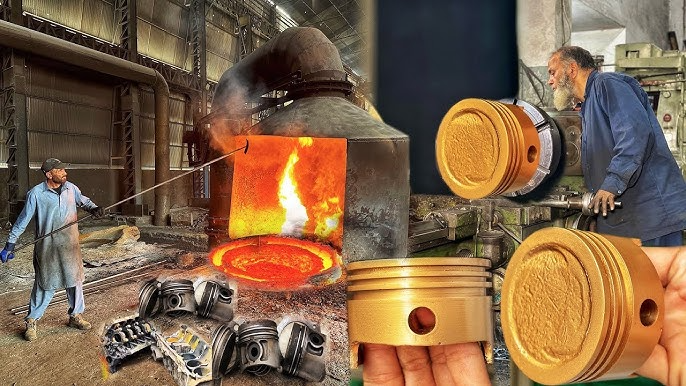

2. Heating the Material

Once the raw materials are selected, they are heated to a specific temperature to make them malleable.

This heating process is usually done in a furnace, where the metal is brought to its forging temperature. Proper heating is essential for effective shaping, as it reduces the risk of cracking and improves ductility.

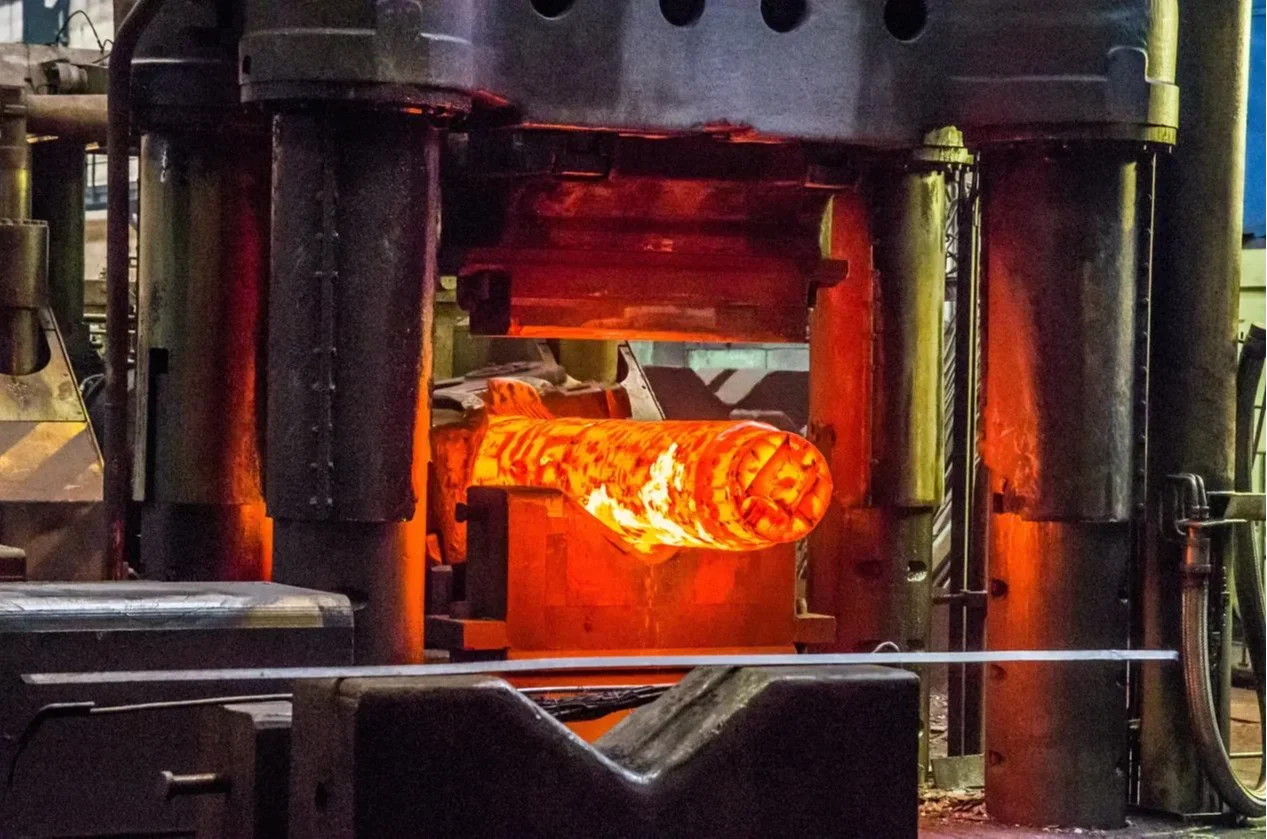

3. Shaping the Metal

After heating, the malleable metal is placed under a hydraulic press or hammer to begin the shaping process. The choice between hydraulic presses and hammers depends on the desired final shape, size, and specifications of the forged part.

Skilled workers carefully monitor the process to ensure precision and consistency, which are crucial for producing high-quality components.

4. Cooling and Finishing

Once the forging process is complete, the metal is cooled gradually to avoid thermal shock, which can weaken the material.

After cooling, the forged products undergo finishing processes such as machining, grinding, or polishing to meet specific tolerances and surface quality requirements.

Key Players in Pakistan’s Heavy Forging Industry

Several companies in Pakistan specialize in heavy forging, contributing significantly to the sector’s growth. Notable players include:

- Pakistan Steel Mills: A state-owned enterprise that produces a wide range of steel products, including forged components.

- Ravi Forgings: Known for manufacturing high-quality forged products for automotive and industrial applications.

- Aisha Steel Mills: A prominent player in the steel industry, providing forged products to various sectors.

These companies invest in advanced technology and skilled labor to enhance their production capabilities and meet international standards.

Benefits of Heavy Forging in Pakistan

1. Enhanced Strength and Durability

Heavy forging improves the mechanical properties of metals, resulting in components that can withstand extreme conditions. This durability is essential for industries such as construction and automotive, where safety and reliability are paramount.

2. Cost-Effectiveness

Forging processes often result in minimal material wastage compared to other manufacturing methods.

This efficiency helps reduce production costs, making forged components more economically viable for manufacturers and consumers.

3. Versatility

Heavy forging can be applied to a wide range of materials and shapes, allowing for the production of diverse components tailored to specific applications. This versatility is beneficial for industries looking for customized solutions.

Challenges Facing the Heavy Forging Industry

Despite its growth, the heavy forging industry in Pakistan faces several challenges:

- Lack of Advanced Technology: Many local manufacturers still rely on outdated machinery, hindering their ability to compete with international standards.

- Skilled Labor Shortage: The industry requires skilled workers who are trained in advanced forging techniques. Addressing this skill gap is essential for sustaining growth.

- Environmental Concerns: The forging process can generate emissions and waste, leading to environmental challenges that need to be managed effectively.

Future Prospects

The heavy forging industry in Pakistan is poised for significant growth, driven by increasing demand from domestic and international markets.

By investing in modern technology, enhancing workforce skills, and addressing environmental concerns, Pakistan can establish itself as a key player in the global heavy forging market.

Conclusion

Heavy forging is an essential process in Pakistan’s industrial landscape, contributing to the production of high-strength components for various sectors.

With ongoing advancements and investments in technology and skilled labor, the industry is well-positioned for future growth.

As demand for durable metal products continues to rise, heavy forging work in Pakistan will play a vital role in supporting economic development and meeting the needs of diverse industries.