The manufacturing of CNC compression springs plays a crucial role in various industries, including automotive, aerospace, and electronics.

These springs are vital components that store and release energy, providing stability and support in different applications.

Understanding the process behind the manufacture of CNC compression springs involves exploring the intricacies of the coiling machines used, the materials involved, and the quality assurance measures that ensure each spring meets industry standards.

This article delves into the detailed manufacturing process of CNC compression springs and the pivotal role of coiling machines.

What Are CNC Compression Springs?

CNC compression springs are tightly wound coils designed to absorb energy and resist compressive forces.

They are typically cylindrical in shape and are made from materials such as stainless steel, music wire, or oil-tempered carbon steel.

CNC technology allows for precise control over the dimensions and characteristics of these springs, ensuring high accuracy and repeatability in production.

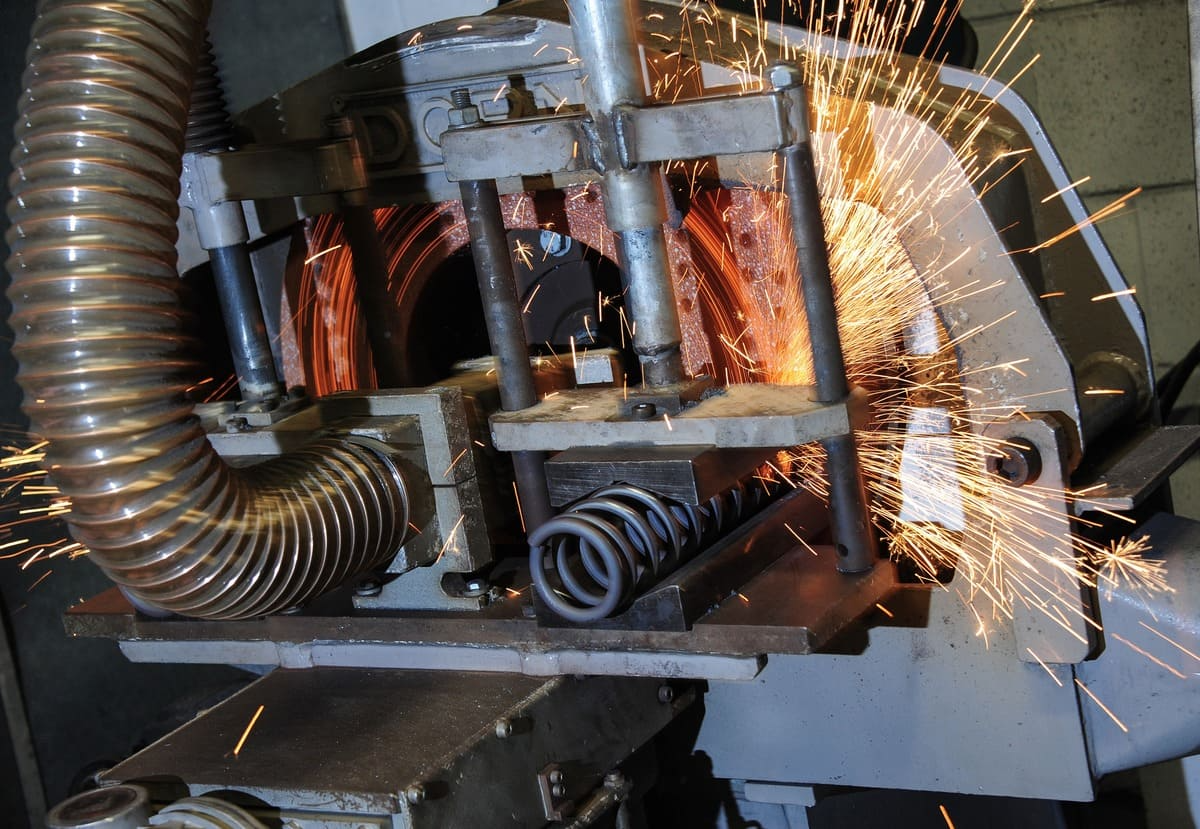

The Role of CNC Coiling Machines

CNC coiling machines are specialized equipment designed to create springs with high precision.

These machines utilize computer numerical control (CNC) technology, which allows for intricate programming of the coiling process. The primary advantages of CNC coiling machines include:

- Precision: CNC machines can produce springs with tight tolerances, ensuring uniformity and performance.

- Automation: The CNC process minimizes human intervention, reducing the chances of errors and increasing production efficiency.

- Customization: Manufacturers can easily adjust the machine settings to create various spring designs, accommodating specific client requirements.

The Manufacturing Process of CNC Compression Springs

The manufacturing process of CNC compression springs can be broken down into several key stages:

1. Material Selection

The first step in the CNC compression spring manufacturing process involves selecting the appropriate material. Factors to consider include the intended application, load requirements, and environmental conditions. Common materials for compression springs include:

- Stainless Steel: Offers excellent corrosion resistance and is suitable for high-stress applications.

- Music Wire: Provides high tensile strength and is often used in general-purpose springs.

- Oil-Tempered Carbon Steel: Offers durability and is cost-effective for various applications.

2. Designing the Spring

Once the material is selected, the next step is designing the spring. This involves creating a detailed specification that includes:

- Wire Diameter: Determines the spring’s strength and load capacity.

- Outside Diameter: Influences the spring’s fit within a specific assembly.

- Free Length: Refers to the length of the spring when not under load.

- Coil Count: The number of coils affects the spring’s characteristics, such as stiffness and deflection.

Manufacturers often use CAD (Computer-Aided Design) software to visualize the spring design and perform simulations to predict performance under various conditions.

3. Setting Up the CNC Coiling Machine

With the design in hand, the next step is to set up the CNC coiling machine. This process involves:

- Loading the Material: The selected wire is fed into the machine, where it will be coiled into the spring shape.

- Programming the Machine: Technicians input the spring specifications into the CNC system, programming the machine to follow the desired coil pattern.

- Adjusting Settings: Parameters such as coil pitch, feed rate, and tension are calibrated to ensure optimal spring formation.

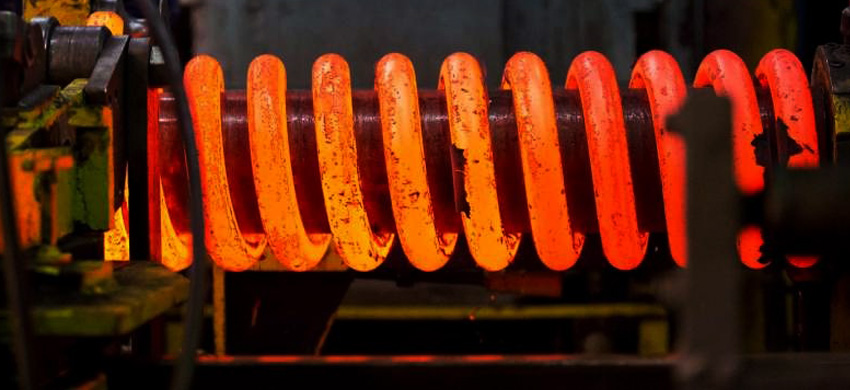

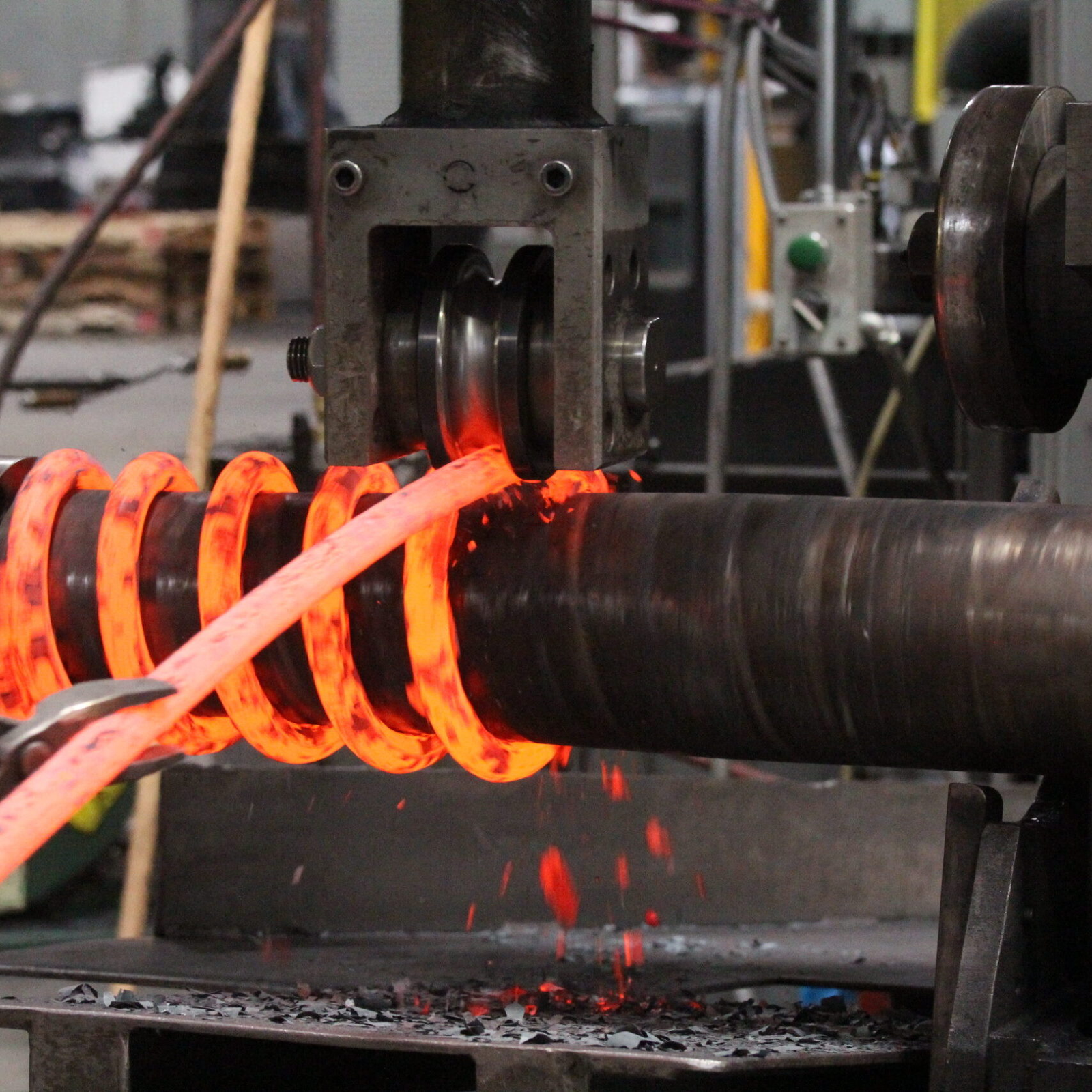

4. Coiling the Springs

The heart of the manufacturing process is the coiling operation. The CNC coiling machine utilizes a rotating mandrel to shape the wire into the desired spring form. This process involves several key actions:

- Winding the Wire: The machine coils the wire around the mandrel according to the programmed specifications.

- Controlling Tension: Maintaining consistent tension during coiling is crucial to ensure the spring’s structural integrity and performance.

- Cooling and Tempering: Depending on the material, springs may undergo a tempering process after coiling to enhance their strength and flexibility.

5. Cutting and Finishing

After the springs are coiled, they need to be cut to the desired length. This is typically done using a precision cutting tool integrated into the CNC machine. After cutting, the springs may undergo finishing processes, such as:

- Shot Peening: A process that enhances fatigue resistance by inducing compressive stress on the surface of the spring.

- Surface Treatment: Applying coatings or finishes to improve corrosion resistance or reduce friction.

- Deburring: Removing sharp edges or burrs from the springs to ensure safety and performance.

6. Quality Control

Quality control is paramount in the manufacturing process of CNC compression springs. This stage involves several inspections to ensure that the springs meet the required specifications. Key quality control measures include:

- Dimensional Inspection: Measuring the springs to ensure they match the design specifications for dimensions, wire diameter, and coil count.

- Load Testing: Subjecting the springs to load tests to evaluate their performance under stress.

- Visual Inspection: Checking for surface defects, such as cracks or uneven coatings, which could affect the spring’s performance.

7. Packaging and Delivery

Once the springs pass quality control, they are carefully packaged to prevent damage during transport. Proper labeling and documentation accompany the packaging to ensure clear communication of specifications and quality assurance.

Conclusion

The process of manufacturing CNC compression springs is a sophisticated operation that combines advanced technology with meticulous craftsmanship.

By utilizing CNC coiling machines, manufacturers can produce high-quality springs with precision and efficiency, meeting the diverse needs of various industries.

The stages outlined in this article—from material selection to quality control—highlight the complexity and importance of each step in ensuring the performance and reliability of compression springs.

As industries continue to evolve, the demand for high-quality CNC compression springs will undoubtedly grow, underscoring the significance of manufacturers in this field.

Whether you are a manufacturer, engineer, or buyer, understanding this process provides valuable insights into the quality and reliability of the components essential for modern engineering applications.

Watch the full video here: